Induction Hardened, Quench & Tempered Steel Bar - Peeled & Ground Finish.

Re - State-of-the-art facility for supply of HARDNED Bar through Induction Quench & Temper Line from the world-renowned manufacturer - Inductotherm Group.

We at P. SOOD & CO. have always believed in adopting the latest technology for the Heat Treatment of steel bars & wires -

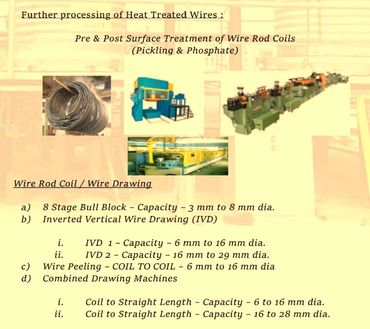

Soft Annealing / Spheroids Annealing, Pickling & Phosphating of wire rods, cold drawing of bars and coils, peeling and grinding bars, Induction Quench & Tempering we offer a complete array of services for the HEAT TREATMENT OF STEEL BARS AND WIRES.

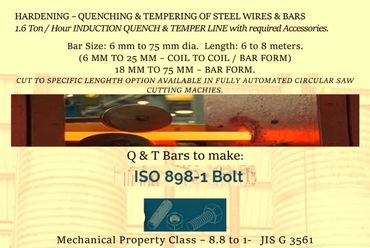

We have commissioned 1.6 Ton / Hour INDUCTION QUENCH & TEMPER LINE with a size range – of 24 mm to 75 mm diameter and length – up to 8 Meters for the supply of Single-bar heat treatment that enables the highest quality and optimum utilization of the material potential through controlled adjustment of the microstructure and steel properties bar by bar.

This leads to homogeneous mechanical properties across the entire bar and batch, which meets the strict requirements of the automotive, oil fields, windmill fasteners and other industries as per DIN tolerances and standards.

Steel bars are tempered as per CQI-9 guidelines.

Our sister concerns are an IATF 16949: 2016 certified company, with in house laboratory accredited to NABL – 17025. We are authorized sales and marketing agents forthem.

The dimensions of the heating coils for induction heating are adapted to the bar steel diameter, whereby three different dimensions ranging from 20 to 80 millimeters can be selected.

This adaptation achieves a high level of efficiency, as the non-contact heating of the steel becomes more effective.

This increases the energy efficiency and precision of the tempering process, which in turn improves the quality of the steel..

We offer peeled and ground bars as well as the option of cutting off the bar ends and cut-to-length facility.

Product Information:

Grades Treated: All heat-treatable grades of carbon, alloy and martensitic stainless steels (AISI 400 series)

Heat Treatments: Quench and Temper, Thru-hardening, Surface hardening, Normalizing, Stress Relieving.

Bar Products: Hot Finished or Cold Finished Size range: 24 to 75 mm dia.

Length Capacity: 6 to 8 Meters range.

Peeled and Ground Bars.

Cutting–end cutting / Cut to length for product applications.

Other Value-Added Services:

Machine straightening, Demagnetization, Chamfering, Metallurgical support, Complete traceability.

Complete Test Reports, Small Quantities Available, Bundling, Color Coding, Experimental or Trial Orders Encouraged, CQI-9 Heat Treatment System Assessment.

Short lead times, On-time, all-the-time delivery, Overseas packaging.

Get in touch with us

Gaurav Sood

(Partner)

P. SOOD & CO.

Plot NO. 50 (DOOR No.76) SIDCO Industrial Estate Ambattur, Chennai 600 098 Tamil Nadu, India.

M: +91 7358771760

UDYAM – TN-02-0006385

GST No.33AARFP6030A1ZL

PAN AARFP6030A

TAN –CALP20643A

About steel

Hardened Steel- Induction, Quench & Tempering Line.

Hardened Steel- Induction, Quench & Tempering Line.

Hardened Steel- Induction, Quench & Tempering Line.

High-throughput steel bar tempering

The quench and temper lines for long products, such as steel bars, have an induction heating section and a quenching section, followed by tempering induction coils. The heating and tempering coils are usually divided into several controllable zones. This has the advantage that the last zone in each cas

High-throughput steel bar tempering

The quench and temper lines for long products, such as steel bars, have an induction heating section and a quenching section, followed by tempering induction coils. The heating and tempering coils are usually divided into several controllable zones. This has the advantage that the last zone in each case can be used for homogenisation, austenitisation, solution annealing (for stainless steels), or hardness adjustment.

On modern production lines, the quench and temper machines from Inductotherm – (USA) are the standard for tempering tube, wires and bar material. The most impressive features of the quench and temper lines from Inductotherm – (USA) are their high efficiency, accuracy and versatility.

INDUCTIVE SINGLE BAR QUENCH & TEMPER SYSTEMS

Hardened Steel- Induction, Quench & Tempering Line.

Hardened Steel- Induction, Quench & Tempering Line.

The challenge in heat treatment of long products is to achieve low distortion and reproducible processes.

The complex interplay of the transport unit, induction heating and chilling sprinklers speaks for this one-stop solution.

The continuously changing requirements of the different areas of application always give us new guidelines for con

The challenge in heat treatment of long products is to achieve low distortion and reproducible processes.

The complex interplay of the transport unit, induction heating and chilling sprinklers speaks for this one-stop solution.

The continuously changing requirements of the different areas of application always give us new guidelines for consistent optimisation of our systems.

Heat treatment platform for a wide range of dimensions of solid material (bright steel, rolled steel) and tubes

Hardening, annealing, soaking and other heat treatment processes within a cycle

Continuous process monitoring and logging

Key-Benefits -

Customized plant and process design

Excellent homogeneity for quality right down to the core

Reproducible processes ensure reproducible product quality

Energy-efficient production with low maintenance and servicing requirements

Various drive concepts for optimized adaptation to the product range

Comprehensive option catalogue for customized adaptation

Quick changeover and tooling

Our Manufacturing Process

Hardened Steel- Induction, Quench & Tempering Line.

Our Manufacturing Process

Premium quality steel bars up to 6 metres in length.

The bars are individually fed in to the heat-treatment line via a worktable that is 7 metres long. P. SOOD & CO. can therefore process bars with lengths ranging from 2.80 metres to 7 metres.

We match the size of the induction heating coil to the diameter of the round

steel bar being pro

Premium quality steel bars up to 6 metres in length.

The bars are individually fed in to the heat-treatment line via a worktable that is 7 metres long. P. SOOD & CO. can therefore process bars with lengths ranging from 2.80 metres to 7 metres.

We match the size of the induction heating coil to the diameter of the round

steel bar being processed.

Five different coil sizes from 6 mm up to 80 mm are available.

Selecting a coil that closely fits the diameter of the steel bar increases the efficiency of

the non-contact induction heating process. ‘Choosing the coil of best fit improves energy

efficiency, as less electrical power is lost, which is an important criterion in our energy

‘It also means that the heat-treatment process can be carried out even more precisely, which helps to enhance the quality of our

steel products.

Technical details such as these enable P. SOOD & CO. to conduct induction

hardening and tempering of individual steel bars across the entire dimensional range from

6 mm to 80 mm in Wires – 6 mm to 18 mm dia. 20 mm till 80 mm in Straight Lengths.

The set up can be modified to process – Tubes & Pipes too. (Specific information on demand)

COMPLETE SOLUTION FOR HEAT TREATMENT OF STEEL WIRES & BARS.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.